Flexwarm® inside

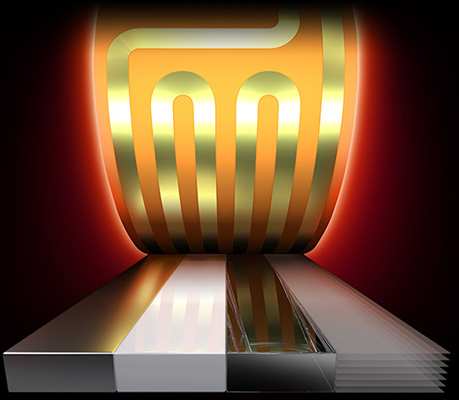

Thick Film Precise Heating Technology

Thick film precise heating technology is the latest heating technology developed by Guangdong Flexwarm Advanced Materials and Technology Co. Ltd. The thick film heating material mainly relies on thick film screen printing technology, which is formed by printing metal slurry with patented formula on the substrate, then sintered by high temperature and dried.

It has various advantages including:

◉High power density

◉Fast heating speed

◉Fast heating rate

◉High mechanical strength

◉Small and light

◉Convenient installation

◉Well-distributed heating areas

◉Long service Life

◉High efficiency and environmental-friendly

◉Safe

It has been widely used in various domestic and international industries, and is gradually replacing traditional heating methods.

-70℃~900℃

Applicable environment

Safe And Precise Heating

0.1℃

Temp That Can Adjust

Resistant To Dry-burning

Diverse Materials

Cost Effective

Flexwarm® inside

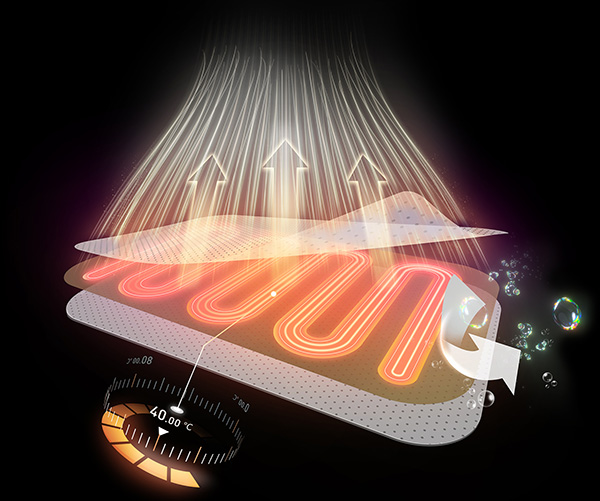

Flexible Heating Film

Thin, soft, bendable, washable, safe and healthy

Application of flexible substrates

Applying Flexwarm’s precise temperature control technology, the patented material is printed on flexible substrate, it is then combined with temperature control sensors and BMS power management system to form a flexible heating system.

Compared with traditional heating materials, this heating system generates heat more uniform, faster and has higher power conversion rate.

In addition, the flexible heating system invented by Flexwarm can release 8 ~ 9 μM far-infrared light wave, which is more beneficial to health than other heaters. The technology has been widely used in the fields of personal care, smart wearables, vehicle equipment, etc.

Excellent properties of flexible heating film:

Light, thin, soft, washable and comfortable

Fast heating rate

Safe and energy-saving, thermal efficiency reaches to 98%

Far-infrared ray can be released, emitting wavelength frequency which is close to human body and can be well-absorbed

Anti-static and anti-corrosion

Flexwarm® inside

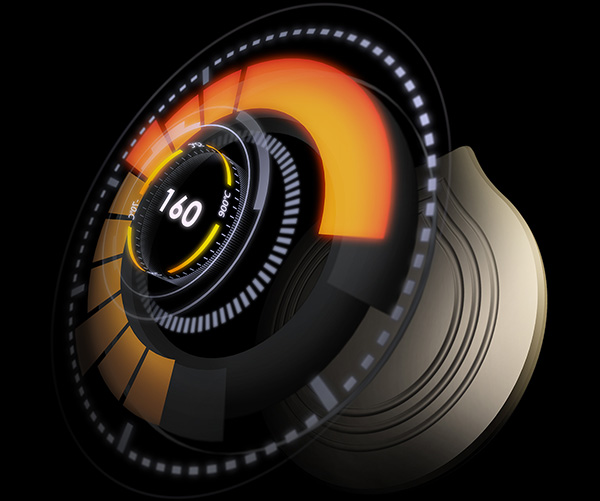

Metal Heating Components

High heating efficiency with small volume

The Application of Metal Substrates

The far infrared thick film heating element on stainless steel substrate was prepared by printing, drying and sintering.

The electric heating element is composed of stainless steel substrate, medium layer, resistor, conductor and covering layer.

Characteristics of new components:

◉Small size

◉High power

◉Large surface heat load

◉Low thermal inertia

◉High thermal efficiency

◉Low power consumption

◉Fast heat up

◉Uniform temperature field

◉No electromagnetic pollution

◉Can be switched on by AC / DC, high / low voltage

◉Environmental friendly, safe and reliable

Excellent properties of heating components:

40~60W/cm² power density

200~300℃/S heating speed

6,000+ hours life span

Save 30%+ energy

95% thermal transformation efficiency

Guarantee For Every User

In the international ITS certified laboratory and the extreme low temperature simulation laboratory, many professional tests are carried out every day for each possible use.

Machine or hand-wash

Bendable and foldable

5kV Pressure resistant test

IPX8 Water-resistant level

Monitoring 1℃ precise temepratrure control

Products

Certifications

CE Certification

KC Mark

FC Certification

Restriction of Hazardous Substances